Machining in a manufacturing standpoint is a procedure of utilizing strength-run equipment to design metals. It really is somewhat a technical expression that problems alloy. It typically refers to metal slicing and the functions of healing metals. Machining is generally categorized into a number of traditional parts. Let’s have a little dialogue about every group. The 1st category concerns the process of grinding the metal into sections. Alloys that are too much to get machined generally undergo the process of grinding. Milling comprises a tire or crushing belt found against the work bit to remove it, and drinking water is handled into the work surface to remove sets off and prevent excessive heat. The crushing method nowadays is much more stylish due to use of eradicating substances instead of equipment. Nonetheless, the usage of chemical compounds is a trouble once we are attempting to have it minimize asymmetrically. In these instances, the handbook device is actually a better concept.

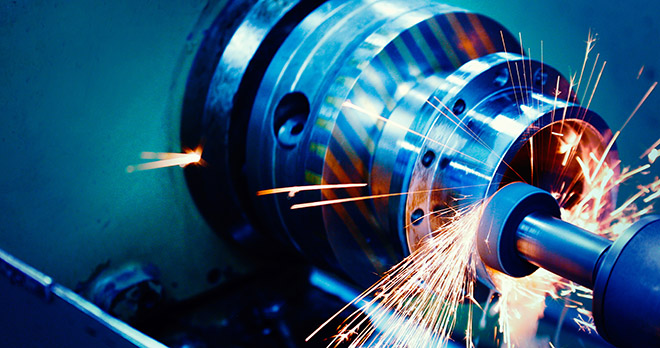

The process of utilizing the manual equipment is called milling. It employs the dill press, and a cutter that moves down where it should be reduce. However, it is significantly less accurate and fewer suggested compared to the mincing process. Another machining method is transforming which is an uncommon method of reducing materials, usually carried out a lathe. It will be the lathe that turns the metal inside and outside, away and on for the blade, and the blade reductions the metal into different symmetrical portion of the materials. Another popular decreasing approach is drilling. The word conveys the use of a drill, or perhaps the drill push against the material to cut. Likewise, it is an excellent method to help remedy the information utilizing equipment that contains a drill bit, to slice the project piece.

Those mentioned above are among the classic ways of doing machining. Those are the common operations widely used to slice materials. On account of improve in technological innovation and the equipment updates, models have evolved into sophisticated functions. They are the alternative ways of doing machining. The unusual means of treating metals utilizes laser beam, drinking water, electrical energy, and chemical substances. Constraints implement though, and using these innovative processes is restricted with more features. Like the water jet strategy, a way of reducing materials by means of the assistance of drinking water, but it is limited to smoother resources. It cannot be employed to hard precious metals, and it is significantly less usable. It can be largely used to materials with breaks.

Cheshire Seals machining technique employs chemical compounds to cut precious metals, but as it’s pricey, it’s significantly less preferred. If you are trying to find better metal precision, effectively this is the smart choice. Nonetheless, developing areas execute their own researches to device more complicated machining processes to assist the coming need for machining. The traditional way of managing alloys is near extinction and this will get replaced with all the modern-day and modern kinds. Developing companies like the less difficult and accurate method of machining to blow up revenue and also to improve fabric quality. Specialists are concentrating only on the effects of unnecessary use of such chemical compounds and ways to decrease unplanned environmental effect.